导语 现代社会里钢筋水泥铸就的高楼林立就好似自然丛林,我们已经使用了这些材料长达数百年,因此也该到了进一步改进的时候。莱斯大学的研究人员就找到了一种方法来将水泥颗粒“编程”成特定的形状,以使混凝土更加坚固,孔隙更少,也更环保。

关键词:科普、译文、混凝土、可编程材料

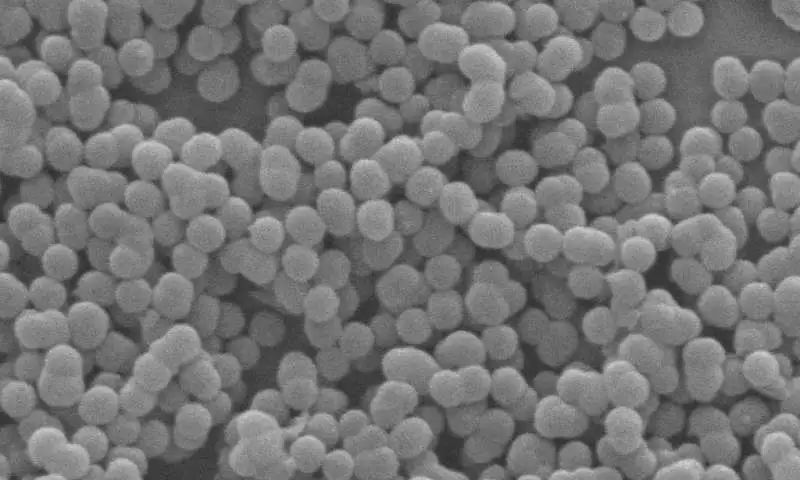

Packed, micron-scale calcium silicate spheres developed at Rice University are a promising material that could lead to stronger and more environmentally friendly concrete. Credit: Multiscale Materials Laboratory/Rice University

由莱斯大学开发的纳米级的填充硅酸钙球是一种很有前途的材料,它可以生产出更坚固,更环保的混凝土。图片来源:多元材料实验室/莱斯大学

Rice University scientists have developed micron-sized calcium silicate spheres that could lead to stronger and greener concrete, the world's most-used synthetic material.

莱斯大学的科学家们开发出了微米级的硅酸钙球,这种球体可以制造出更坚固、更环保的混凝土,这是世界上最常用的合成材料。

To Rice materials scientist Rouzbeh Shahsavari and graduate student Sung Hoon Hwang, the spheres represent building blocks that can be made at low cost and promise to mitigate the energy-intensive techniques now used to make cement, the most common binder in concrete.

对于莱斯的材料科学家Rouzbeh Shahsavari和研究生Sung Hoon Hwang来说,这种球体代表了可以以低成本制造的建筑材料,并且可以缓解当前用于制造水泥的能源密集型技术的压力,其中水泥是混凝土中最常见的粘合剂。

The researchers formed the spheres in a solution around nanoscale seeds of a common detergent-like surfactant. The spheres can be prompted to self-assemble into solids that are stronger, harder, more elastic and more durable than ubiquitous Portland cement.

研究人员在一种类似洗涤剂的表面活性剂的纳米级种子周围的溶液中形成球体。与普通硅酸盐水泥相比,这些球体可以自动组装成更坚固、更硬、更有弹性、更耐用的固体。

"Cement doesn't have the nicest structure," said Shahsavari, an assistant professor of materials science and nanoengineering. "Cement particles are amorphous and disorganized, which makes it a bit vulnerable to cracks. But with this material, we know what our limits are and we can channel polymers or other materials in between the spheres to control the structure from bottom to top and predict more accurately how it could fracture."

“水泥没有最好的结构,”材料科学和纳米工程助理教授Shahsavari说。“水泥颗粒是无定形和无序的,这使得它很容易产生裂缝。但有了这种材料,我们知道我们的极限是什么,我们可以在球体之间引入聚合物或其他材料,从下到上控制结构,更准确地预测它如何断裂。”

He said the spheres are suitable for bone-tissue engineering, insulation, ceramic and composite applications as well as cement.

他说,这种球体适用于骨组织工程,绝缘材料,陶瓷和复合材料以及水泥。

The research appears in the American Chemical Society journal Langmuir.

该研究发表在美国化学学会期刊《Langmuir》上。

The work builds on a 2017 project by Shahsavari and Hwang to develop self-healing materials with porous, microscopic calcium silicate spheres. The new material is not porous, as a solid calcium silicate shell surrounds the surfactant seed.

这项工作以Shahsavari和Hwang在2017年的一个项目为基础,该项目旨在开发具有多孔微观硅酸钙球的自修复材料。这种新材料不是多孔的,因为固体硅酸钙壳包裹着表面活性剂种子。

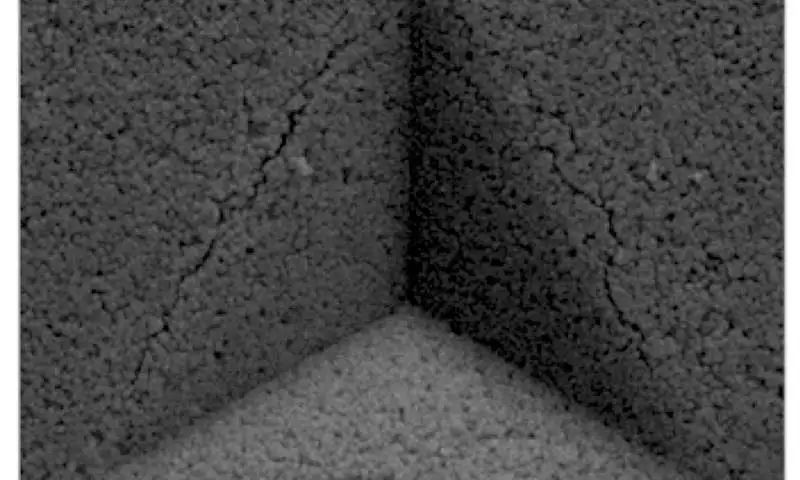

Calcium silicate spheres synthesized at Rice University and packed into a pellet hold together under compression. The spheres are building blocks that can be made at low cost and promise to mitigate the energy-intensive techniques now used to make cement, the most common binder in concrete. Credit: Multiscale Materials Laboratory/Rice University

在莱斯大学合成的硅酸钙球体,在压缩下被压缩成小球。这些球体是可以以低成本制造的建筑材料,有望减轻目前用于制造水泥的能源密集型技术的影响。水泥是混凝土中最常见的粘合剂。图片来源:多元材料实验室/莱斯大学

But like the earlier project, it was inspired by how nature coordinates interfaces between dissimilar materials, particularly in nacre (aka mother of pearl), the material of seashells. Nacre's strength is a result of alternating stiff inorganic and soft organic platelets. Because the spheres imitate that structure, they are considered biomimetic.

但就像早期的项目一样,它的灵感来自于不同材料之间的自然协调,尤其是珍珠(又名珍珠母)贝壳的材料。珍珠的强度是硬的无机血小板和软的有机血小板交替作用的结果。因为球体模仿这种结构,它们被认为是仿生的。

The researchers discovered they could control the size of the spheres that range from 100 to 500 nanometers in diameter by manipulating surfactants, solutions, concentrations and temperatures during manufacture. That allows them to be tuned for applications, Shahsavari said.

研究人员发现,他们可以通过操纵表面活性剂、溶液、浓度和制造过程中的温度来控制直径在100到500纳米之间的球体的大小。 Shahsavari表示,这可以让他们针对应用程序进行调整。

"These are very simple but universal building blocks, two key traits of many biomaterials," Shahsavari said. "They enable advanced functionalities in synthetic materials. Previously, there were attempts to make platelet or fiber building blocks for composites, but this works uses spheres to create strong, tough and adaptable biomimetic materials.

“这些都是非常简单但通用的构件,是许多生物材料的两个关键特征,”Shahsavari说。 “它们使合成材料具有先进的功能。在此之前,人们曾试图制造用于复合材料的血小板或纤维构建块,但这一工程使用球体来制造坚固、坚韧和适应性强的仿生材料。

"Sphere shapes are important because they are far easier to synthesize, self-assemble and scale up from chemistry and large-scale manufacturing standpoints."

“球体形状很重要,因为它们更容易合成,自组装,并且从化学和大规模制造的角度扩大规模。”

In tests, the researchers used two common surfactants to make spheres and compressed their products into pellets for testing. They learned that DTAB-based pellets compacted best and were tougher, with a higher elastic modulus, than either CTAB pellets or common cement. They also showed high electrical resistance.

在测试中,研究人员使用两种常见的表面活性剂制造球体,并将其产品压缩成颗粒进行测试。他们了解到与CTAB颗粒或普通水泥相比,基于DTAB的颗粒压实效果最好,硬度更好,弹性模量也更高。它们还表现出高电阻。

Shahsavari said the size and shape of particles in general have a significant effect on the mechanical properties and durability of bulk materials like concrete. "It is very beneficial to have something you can control as opposed to a material that is random by nature," he said. "Further, one can mix spheres with different diameters to fill the gaps between the self-assembled structures, leading to higher packing densities and thus mechanical and durability properties."

Shahsavari说,颗粒的大小和形状一般对混凝土等散装材料的机械性能和耐久性有显着影响。他说:“拥有一些你可以控制的东西是非常有益的,而不是随机性质的材料。”“此外,人们还可以将不同直径的球体混合,以填充自组装结构之间的空隙,从而提高填料密度,从而提高机械性能和耐久性。”

He said increasing the strength of cement allows manufacturers to use less concrete, decreasing not only weight but also the energy required to make it and the carbon emissions associated with cement's manufacture. Because spheres pack more efficiently than the ragged particles found in common cement, the resulting material will be more resistant to damaging ions from water and other contaminants and should require less maintenance and less-frequent replacement.

他说,增加水泥的强度可以使制造商减少混凝土的使用量,不仅减少了重量,还减少了制造水泥所需的能源以及与水泥生产相关的碳排放。由于球体比普通水泥中的参差不齐的颗粒更有效地填充,因此所得到的材料将更耐受来自水和其他污染物的破坏性离子,并且需要更少的维护和更少的更换频率。

(责任编辑:周姚)